About us

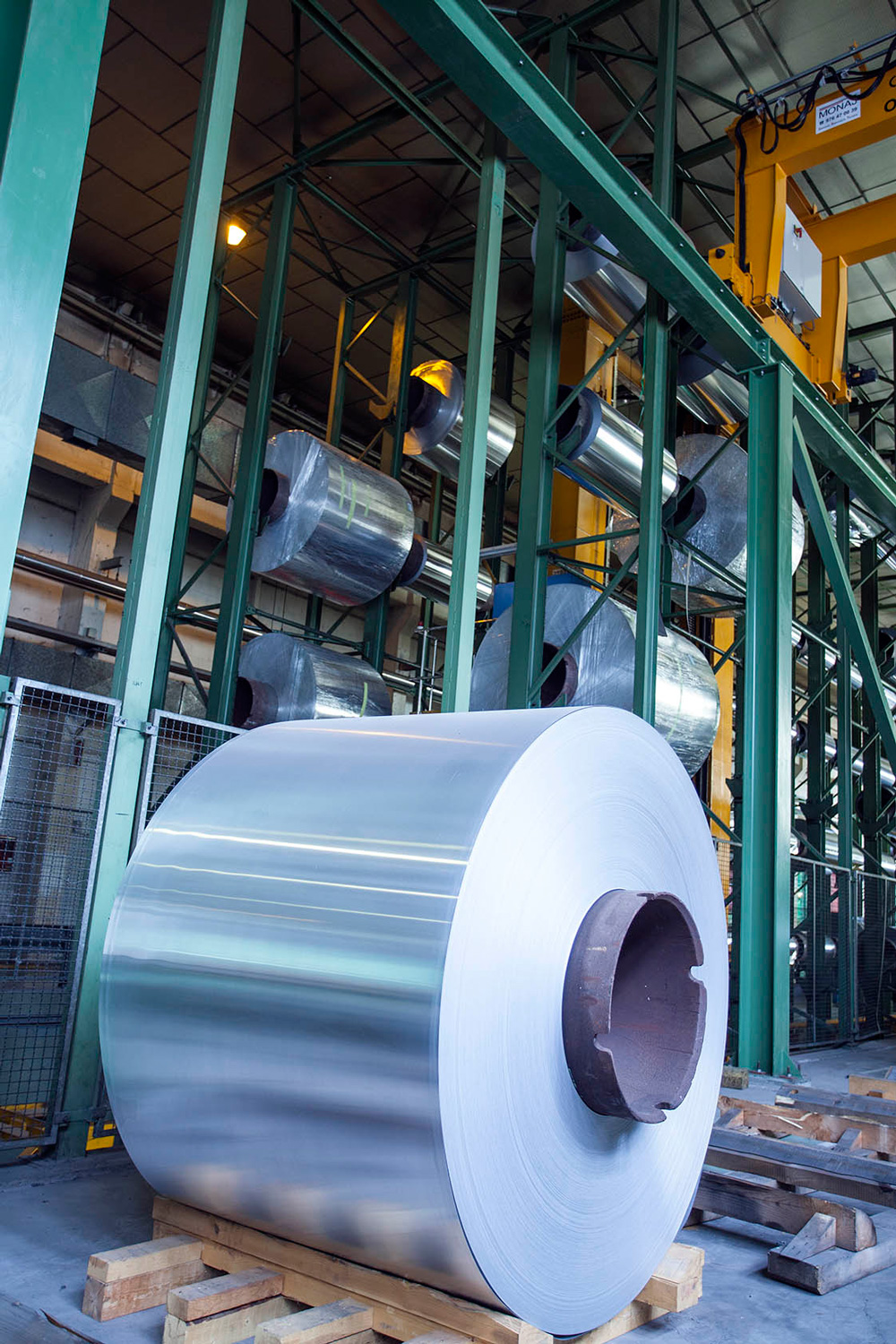

IIBERFOIL, with almost 100 years of history in the world of aluminium, is a European manufacturer of high-quality aluminium coils, with an industrial plant of 110.000m2 located in Sabiñánigo, Huesca (Spain).

The advanced machinery and the great existing professional team with wide experience, make IBERFOIL to be positioned as a reference in the market, thanks to the quality of its products and the service to the client.

From its beginnings, IBERFOIL has been making investments allowing a great growth in market share and new products, therefore, it can offer a wide range of aluminium products, from 6 microns to 6 mm thickness, and aluminium coils up to 1750 mm width.

IBERFOIL HAS...

Four thin sheet aluminium

Three thin sheet aluminium rolling mills, with speeds up to 1800 meters per minute and process control systems that guarantee and control continuously the thickness and flatness of the aluminium. In addition, each mill, has a detailed surface control system, based on a brand detector that certifies the maximum quality of each manufactured coil.

Four separators and two slitters

Two foil slitters and one coil slitter, as well as a tension levelling line that allow to adjust and customise the width requested by each customer with only ±1 mm tolerance at a speed of up to 1200 meters per minute. Coil splicing is carried out by means of an ultrasound method that allows us to offer our customers highly personalised products with great lengths in each coil.

Fourteen annealing furnaces

Twelve annealing furnaces for Foil and two for Coil to obtain the mechanical characteristics according to each customer's specifications to guarantee excellent performance. Each furnace allows heat treatments that are automatically adjusted both in terms of temperature and time, guaranteeing the most optimum result. The chassis, which are located inside each furnace, advance through each stage of the production process fully automatically, from the intermediate warehouse, to the furnace and finally to the packaging stage, achieving minimum product handling.

A vertical automatic warehouse with a capacity of 110 coils

About 1,400 tons supplies the entire production process automatically, minimising manufacturing times and maximising results.

Four metal roll grinding machines

Three metal roll grinding machines and one for rubber and polyurethane rolls that manage to eliminate any defect that may have appeared in the production process, thus guaranteeing maximum quality and safety of all our products.

A vertical automatic warehouse with a capacity of 110 coils

About 1,400 tons supplies the entire production process automatically, minimising manufacturing times and maximising results.

Four metal roll grinding machines

Three metal roll grinding machines and one for rubber and polyurethane rolls that manage to eliminate any defect that may have appeared in the production process, thus guaranteeing maximum quality and safety of all our products.

IBERFOIL

22600 Sabiñánigo Huesca,

SPAIN

info@iberfoil.com

General Phone: +34 97 448 41 00

Commercial Phone: +34 97 448 41 55